Chain Tensioners – Stocked for the Trade

Chain tensioners take up slack, reduce wear, and keep drives running right. Whether you’re dealing with fluctuating loads, vibration, or thermal expansion, a good tensioner keeps the chain tracking true.

They’re quick to install, easy to adjust, and proven to extend chain and sprocket life across thousands of trade setups.

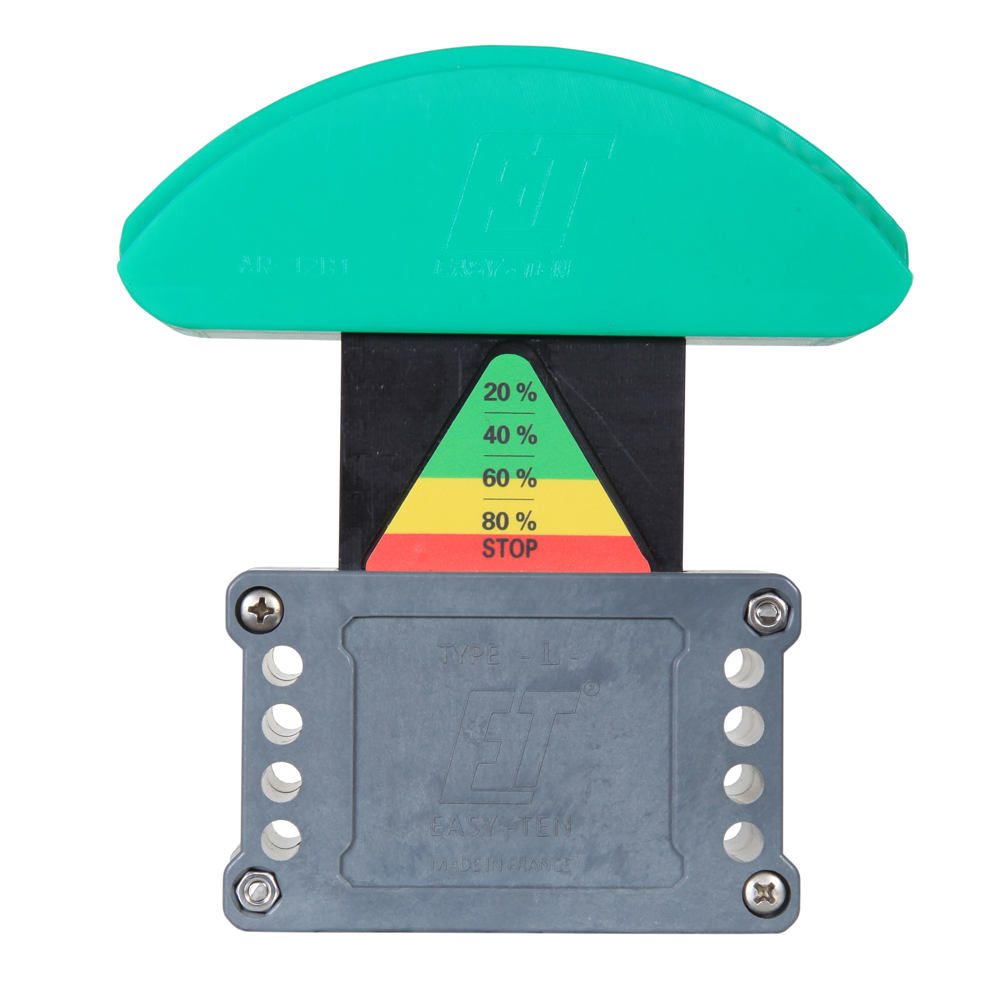

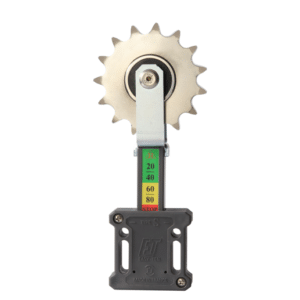

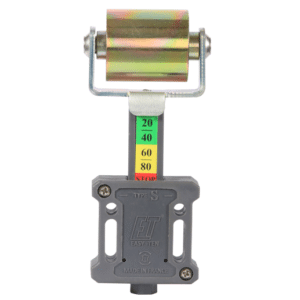

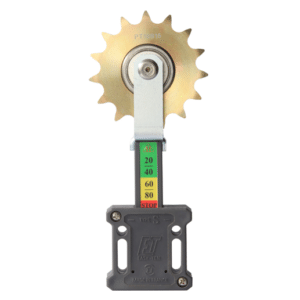

Godiva Bearings stocks Easyten chain tensioners and accessories — ready to fit, ready to work.

What Are Chain Tensioners?

Chain tensioners are devices that maintain proper tension in chain drives. They improve:

- Chain alignment

- Load distribution

- System efficiency

By keeping consistent chain tension, they:

- Prevent slip and jump

- Reduce vibration and noise

- Protect sprockets and shafts

Godiva supplies:

- Fixed and automatic tensioners

- Spring-loaded tensioners

- Adjustable arm tensioners

- Easyten brand systems with sprockets or rollers

What Are They Made Of?

Built for industrial use, our chain tensioners feature:

- Steel arms and brackets – For rigidity and strength

- Nylon or polymer idler rollers – For quiet, low-wear contact

- Steel or polymer sprockets – Where rotation is required

- Springs or elastomers – For consistent force application

Available with:

- Bolt-on brackets

- Slotted mounting plates

- Replaceable idler elements

Where Are Chain Tensioners Used?

Typically, they will show up anywhere chain needs to stay tight. Common applications include:

- Conveyor systems: To manage slack from thermal movement or load changes

- Agricultural equipment: For variable terrain and start/stop motion

- Packaging machinery: Where downtime is costly

- Material handling: In hoists, elevators, and drives

- Timber and sawmills: Where debris and heat change chain length

- OEM builds and retrofits: Clean installation with minimal rework

What Do Chain Tensioners Help Prevent?

Used correctly, tensioners prevent:

- Chain whip or snatch under load

- Uneven sprocket wear from loose chain

- High noise levels in rotating systems

- Shock loads to shafts and bearings

- Slipped chains causing timing issues

They smooth the motion and protect the kit.

Installation, Use and Maintenance Tips

For best results:

- Position tensioner on the slack side of the drive

- Allow contact over several chain links

- Use light preload – don’t overtighten

- Regularly inspect rollers or sprockets for wear

- Grease pivot points if not self-lubricating

Mounting flexibility makes them ideal for retrofit or design-in.

Conclusion: Keeping Chain in Check

Chain tensioners are simple insurance. They keep drives quiet, tight, and on track. Less wear. Less fuss.

Godiva Bearings stocks Easyten tensioners and spares — proven by the trade and supported by real-world advice.